manual awning parts

- by leo

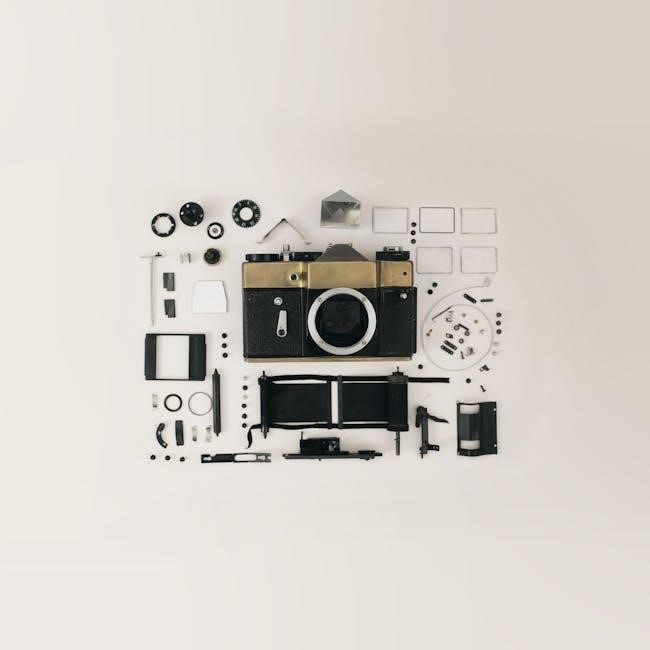

Manual Awning Parts: A Comprehensive Overview

Manual awnings offer shade with simple operation, relying on components like fabric, frames, and hardware for functionality. Understanding these parts ensures proper maintenance.

Manual awnings represent a classic shading solution, prized for their simplicity and affordability. Unlike powered models, they operate through a hand-crank mechanism, offering direct control and eliminating electrical requirements. These awnings consist of several key parts working in harmony: durable awning fabric stretched over a supporting frame, secured by robust mounting brackets.

The crank handle extends and retracts the awning, while awning pins and clips ensure secure positioning. Understanding these fundamental components is crucial for installation, maintenance, and repair, allowing owners to maximize their awning’s lifespan and enjoy years of reliable shade.

Awning Fabric and Materials

Awning fabric selection is paramount, influencing durability, weather resistance, and aesthetic appeal. Common materials include acrylic, known for its vibrant color retention and water repellency, and polyester, offering affordability and resistance to stretching. Vinyl provides excellent waterproofing but can be heavier.

The fabric’s weight, measured in ounces, impacts its ability to withstand wind and rain. Solution-dyed fabrics are preferred, as the color is integrated into the fibers, preventing fading. Proper fabric care, including regular cleaning, extends the awning’s life and maintains its appearance.

Awning Frame Components

The awning frame provides structural support, typically constructed from aluminum, steel, or a combination. These materials balance strength with weight considerations. The frame consists of several key elements working in unison.

These include the roller tube, which winds and unwinds the fabric, side rails guiding the fabric’s movement, and support arms extending the awning outwards. The quality of these components directly affects the awning’s stability and longevity, especially when exposed to wind and weather.

Awning Roller Tube

The awning roller tube is a crucial component, serving as the central winding mechanism for the awning fabric. Typically made of aluminum, it’s designed for strength and to resist bending under the fabric’s weight. Its diameter influences the awning’s ability to handle larger fabric widths and withstand wind pressure.

A quality roller tube ensures smooth retraction and extension. Internal spring tension, or a manual crank system, facilitates this operation. Proper maintenance, including lubrication, is vital for preventing binding and ensuring long-term functionality.

Awning Side Rails

Awning side rails, often constructed from aluminum, provide structural support and guide the fabric as it extends and retracts. These rails run along the length of the awning, maintaining the fabric’s shape and preventing sagging. They house the fabric’s edge and contribute significantly to the awning’s overall stability.

The rails’ design impacts wind resistance; robust rails minimize flapping and potential damage. Secure attachment to the roller tube and proper alignment are essential for smooth operation and longevity. Inspecting rails for bends or damage is key during maintenance.

Awning Support Arms

Awning support arms are crucial for extending and holding the awning fabric at a desired angle. Typically made of aluminum or steel, these arms pivot outwards, providing the necessary support to prevent sagging and ensure stability. The number of arms depends on the awning’s size and projection.

Adjustable arms allow for customized positioning, optimizing shade and accommodating varying sun angles. Regular inspection for corrosion or looseness is vital for safe operation. Properly functioning support arms are essential for withstanding wind and weather conditions.

Awning Hardware

Awning hardware encompasses all the smaller, yet vital, components that facilitate operation and secure installation. This includes mounting brackets, essential for attaching the awning to a surface – house, RV, or caravan. The crank handle mechanism allows for manual retraction and extension of the awning fabric.

Furthermore, awning pins and clips secure the fabric to the roller tube and frame, ensuring a taut and stable shade. Quality hardware is crucial for durability and smooth functionality, resisting rust and wear for long-lasting performance.

Mounting Brackets

Mounting brackets are the foundational hardware connecting your manual awning to the supporting structure, be it a building or vehicle. Their design varies based on the surface – wall-mounted, roof-mounted, or RV-specific. The number of brackets needed depends on the awning’s size; larger awnings require more for stability.

Robust construction is paramount, utilizing materials like aluminum or steel to withstand wind loads and vibrations. Proper installation, ensuring secure attachment to solid framing, is critical for safety and preventing damage.

Crank Handle Mechanism

The crank handle mechanism is the core of manual awning operation, enabling retraction and extension. It typically consists of a gear reduction system, converting rotational force into the necessary torque to roll up or unroll the awning fabric. A metal crank handle inserts into a gearbox, often located within the awning’s housing.

Regular lubrication of the gears is essential for smooth operation and preventing corrosion. Inspecting the handle and gearbox for damage ensures continued functionality, avoiding frustrating operational issues and extending the awning’s lifespan.

Awning Pins and Clips

Awning pins and clips are small but crucial components securing the fabric to the awning’s frame. These fasteners prevent sagging and maintain a taut, clean appearance. Different types exist, including specialized clips for valances or drop curtains, and pins designed for specific fabric thicknesses.

Regularly check these fasteners for rust, breakage, or loosening, as they are exposed to the elements. Replacing damaged pins or clips promptly prevents fabric tearing and ensures the awning functions correctly, maintaining its protective qualities.

Awning Case and Housing

The awning case and housing, often constructed from aluminum or durable plastic, serves as protective enclosure when the awning is retracted. This casing shields the fabric from harsh weather – sun, rain, and wind – extending its lifespan and preventing damage; A well-maintained case prevents mildew and debris buildup.

Inspect the housing regularly for cracks or corrosion. Ensuring a secure closure is vital; a damaged case compromises the awning’s protection, leading to costly repairs or replacements. Proper housing maintenance is key.

Awning Valances and Drop Curtains

Awning valances and drop curtains enhance privacy and protection from the elements, extending the usable space beneath the awning. Valances, the fabric flap along the awning’s edge, block low-angle sun, reducing glare and heat. Drop curtains, often sold separately, provide side enclosure, shielding from wind and light rain.

These additions are typically made from durable, weather-resistant fabrics like acrylic or polyester. Secure attachment is crucial; check regularly for tears or loose fastenings to maintain optimal performance and protection.

Specific Manual Awning Types & Parts

Retractable manual awnings feature a roller tube, fabric, side rails, and support arms, all operated by a crank handle. Caravan/Camper awnings differ, often utilizing lightweight aluminum frames and specialized mounting brackets designed for vehicle attachment.

Camper awnings frequently incorporate unique tensioning systems and adjustable poles for varied terrain. Understanding these distinctions is vital when sourcing replacement parts; ensure compatibility with your specific awning model for a secure and functional fit.

Retractable Manual Awnings ⸺ Parts Breakdown

Retractable awnings consist of a roller tube housing the fabric, awning side rails guiding its extension, and adjustable support arms providing stability. The crank handle mechanism facilitates retraction and extension, while awning pins and clips secure the fabric.

Mounting brackets attach the assembly to a structure. The awning case protects the rolled-up fabric. Replacement often involves these core components; identifying the correct part numbers is crucial for a seamless repair and continued functionality of your shading solution.

Caravan/Camper Awnings ⸺ Unique Components

Camper awnings often feature specialized mounting brackets designed for RV sides, differing from home installations. They frequently incorporate lightweight awning fabric to minimize weight. Unique awning pins and clips secure the fabric against wind, crucial for travel. Some utilize a simple lever system instead of a crank handle.

Awning cases are streamlined for aerodynamics. Replacement parts must match the RV’s specific model. Understanding these distinctions is vital when repairing or upgrading a caravan’s shade solution, ensuring compatibility and reliable operation.

Awning Repair and Replacement Parts

Identifying damaged awning parts is the first step in repair; common issues include torn awning fabric, broken support arms, and faulty crank handle mechanisms. Replacement awning pins and clips are frequently needed after windy conditions. Mounting brackets can corrode, requiring replacement for safety.

When sourcing parts, knowing the awning’s model number is crucial. Online diagrams and parts lists aid identification. Prioritize quality replacements to ensure longevity and continued functionality of your manual awning system, avoiding future repairs.

Identifying Awning Parts for Replacement

Accurate identification of awning parts is vital for successful repairs. Begin by consulting the original awning documentation, if available, for a parts diagram. Note the manufacturer and model number. Carefully examine the damaged component, comparing it to online catalogs or parts lists.

Pay attention to dimensions, material, and mounting style. Photographs can be helpful when ordering online. If unsure, contact the awning manufacturer or a specialized RV parts supplier for assistance. Correct identification prevents purchasing incompatible replacements.

Common Awning Repair Issues & Parts Needed

Frequent issues with manual awnings include fabric tears requiring patch kits or full fabric replacement. Broken support arms often necessitate new arms or repair brackets. A malfunctioning crank handle mechanism may need a replacement handle, gears, or spring.

Damaged awning pins and clips are easily replaced. Worn mounting brackets compromise stability and require upgrading. Identifying the specific problem dictates the necessary parts; a thorough inspection is crucial before ordering replacements.

Awning Installation Considerations

Proper awning installation demands careful attention to mounting surfaces and hardware selection. Ensure the wall can support the awning’s weight; use appropriate mounting brackets designed for the material – wood, brick, or siding.

Awning height and angle adjustment are vital for optimal shade and weather protection. Consider sun exposure and desired coverage. Securely fasten all components, verifying stability before use. Incorrect installation can lead to damage or safety hazards, so professional help is advisable.

Choosing the Right Mounting Hardware

Selecting suitable mounting hardware is crucial for a secure awning installation. Consider the wall’s construction – wood, stucco, brick, or concrete – as each requires specific anchors and brackets. Heavy-duty brackets are essential for larger awnings, ensuring they can withstand wind and weight.

Stainless steel hardware resists corrosion, prolonging the awning’s lifespan. Verify the brackets are compatible with your awning’s roller tube diameter. Always follow the manufacturer’s guidelines for hardware specifications and installation procedures.

Awning Height and Angle Adjustment

Proper awning height and angle maximize shade and minimize wind resistance. Generally, mount the awning high enough to allow comfortable passage underneath, typically around 7-9 feet. Adjusting the angle is vital; a steeper angle provides more shade during lower sun positions, while a shallower angle is better for higher sun.

Many manual awnings offer adjustable support arms allowing for angle customization. Consider the sun’s path and your desired shading effect when setting the angle. Securely tighten all adjustments to prevent slippage.

Awning Maintenance and Care

Regular awning maintenance extends its lifespan and ensures optimal performance. Cleaning the fabric is crucial; use mild soap and water, avoiding harsh chemicals or abrasive cleaners. Inspect the awning regularly for tears, mildew, or damage to the frame.

Lubricating moving parts, like the crank handle mechanism and support arms, prevents corrosion and ensures smooth operation. Retract the awning during severe weather to prevent damage from wind or heavy rain. Proper care preserves its beauty and functionality.

Cleaning and Protecting Awning Fabric

Maintaining your awning fabric involves gentle cleaning to remove dirt and mildew. Use a soft brush with mild soap and water, rinsing thoroughly. Avoid bleach or strong detergents, as they can damage the material. For stubborn stains, specialized awning cleaners are available.

Protecting the fabric from the elements is vital. Consider applying a fabric protectant spray to repel water and resist fading. Regularly inspect for tears and address them promptly to prevent further damage. Proper cleaning and protection prolong the awning’s life.

Lubricating Moving Parts

Regular lubrication is crucial for smooth awning operation. Focus on the crank handle mechanism, awning pins, and any pivot points within the support arms. Use a silicone-based lubricant to prevent rust and ensure effortless extension and retraction. Avoid oil-based lubricants, as they attract dirt.

Apply lubricant sparingly, wiping away any excess. Inspect these parts during each use and lubricate as needed. Proper lubrication reduces friction, preventing wear and tear, and extending the lifespan of your manual awning’s components.

Awning Safety Features

Manual awnings, while straightforward, require attention to safety. Secure awning tie-down kits are essential, particularly in windy conditions, preventing unexpected retraction or detachment. Regularly inspect mounting brackets for corrosion or looseness, ensuring a firm hold.

Be mindful of the awning’s angle; excessive incline can create instability. Never operate a damaged awning, and avoid standing directly underneath during extension or retraction. Prioritizing these safety checks protects both people and property from potential hazards associated with awning use.

Awning Accessories

Enhance your manual awning experience with useful accessories! Awning lights provide illumination for extended evening enjoyment, creating a welcoming outdoor space. Awning tie-down kits offer crucial stability in windy weather, securing the awning and preventing damage.

Consider side panels or screens for added privacy and protection from the elements. These additions maximize the functionality of your awning, transforming it into a versatile outdoor living area. Properly selected accessories extend the usability and enjoyment of your manual awning system.

Awning Lights

Awning lights dramatically extend the usability of your outdoor space, providing illumination after sunset. Available in various styles – LED strip lights, spotlights, or decorative lanterns – they create a warm and inviting ambiance. Many options operate on battery power or can be wired into an existing outdoor electrical source.

Choosing the right awning lights depends on your desired aesthetic and power preferences. Consider waterproof and durable fixtures designed for outdoor use, ensuring long-lasting performance and safety while enjoying your manual awning.

Awning Tie-Down Kits

Awning tie-down kits are crucial for securing your manual awning against strong winds, preventing damage and ensuring safety. These kits typically include heavy-duty straps, ground stakes, and buckles designed to anchor the awning firmly to the ground. Proper installation is vital for effectiveness.

Investing in a reliable tie-down system safeguards your investment and provides peace of mind, especially during inclement weather. Regularly inspect the straps and stakes for wear and tear, replacing them as needed to maintain optimal security for your outdoor setup.

Related posts:

Don’t let a broken awning ruin your outdoor fun! We’ve got all the manual awning parts you need for DIY repair & replacement. Shop now & save!

Posted in Manuals